Finn Recycling receives first commercial order for sand regeneration service in Germany - global market leader Siempelkamp as customer

Siempelkamp Giesserei, the world market leader for hand-mold casting solutions, is the first large foundry in Germany to start working with Finn Recycling on sand recovery. The aim of the cooperation is to increase the reuse of sand for the production moulds at the Krefeld foundry.

Date

24.03.2023

Written by

Resand

Siempelkamp Giesserei, the world market leader for hand-mold casting solutions, is the first large foundry in Germany to start working with Finn Recycling on sand recovery. The aim of the cooperation is to increase the reuse of sand for the production moulds at the Krefeld foundry.

Finn Recycling's solution helps Siempelkamp to increase the recycling rate, conserve resources and save costs

The Siempelkamp Foundry requires almost 1,000 tons of foundry sand per day and already recycles to approximately 95 percent of the sand. Significantly reducing the remainder will help reduce the foundry's ecological footprint and achieve closed material cycles. The disposal of used foundry sand in landfills is very expensive and the space available for this in Germany is becoming increasingly scarce.

"As a leading industrial company, we want to move even faster in terms of active environmental protection, sustainability, and efficiency and increase our recycling rate further. We are very happy to have found an innovative partner in Finn Recycling who establishes solutions together with us in order to support our way of Mission Green and the closing of material cycles," comments Dr. Georg Geier.

Finn Recycling’s patented technology and innovative business model

Finn Recycling has developed its unique sand regeneration solution for a long period of time and it has already successfully implemented several projects in Finland with local foundries. In Germany, the company has a production unit with the University of Freiberg focusing on R&D. Finn Recycling's patented solution enables the regenerated sand to be equal or higher quality than virgin sand and can be reused as such in the foundry processes.

Finn Recyclings Sand As A Service (SAAS) solution offers foundries sustainable savings compared to the current practice in the foundry industry. Savings are generated by buying less virgin sand and disposing of less used sand, in addition to which, the transportation and energy costs are reduced. As the used sand regeneration and recycling is offered as a service, it also lowers the capital tied up in foundry operations.

"We want to enable a rethink in the foundry industry and make sand regeneration an integral part of business practices. We offer foundries a rapid, modular and environmentally friendly solution that reduces the need for investment and saves foundries’ operational costs significantly. We are extremely proud and happy to start our first commercial sand regeneration project outside Finland with Siempelkamp, the global leader in its field. Germany is one of the key markets in our growth plans," says Kalle Härkki, CEO of Finn Recycling.

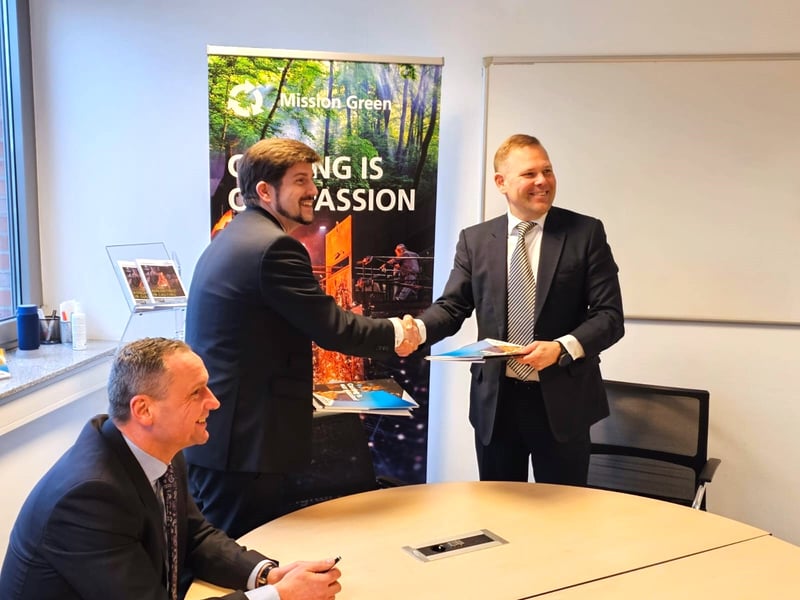

Kalle Härkki, CEO of Finn Recycling Oy on the right, Georg Geier, CEO of Siempelkamp Giesserei in the middle and Dirk How, CEO of Siempelkamp on the left at the signing of the cooperation agreement.

The world is running out of the right kind of sand

Sand is the second most used natural resource in the world after water, and its use is expected to increase with urbanisation and accelerating construction. In addition to carbon emissions, mining has a number of environmental impacts, such as accelerated erosion, air and groundwater pollution and loss of biodiversity. The global foundry industry uses more than 100 million tonnes of sand each year without recycling the used sand generated in the process. This model is unsustainable from both an environmental and a foundry industry perspective.

Finn Recycling’s sand regeneration solution significantly reduces the extraction of new, depleting sand resources and the CO2 emissions from sand use. In addition, sand regeneration significantly reduces the amount of used sand and the need for landfills.

Press contact

Kalle Härkki, CEO

kalle.harkki@finnrecycling.fi

+358405133383

About Finn Recycling

Finn Recycling Oy is a Finnish technology company specializing in sand regeneration. Finn Recycling offers foundries more environmentally friendly and profitable solutions for the use of sand. After a long period of research, Finn Recycling has patented a regeneration technology that allows foundry sand to be processed for reuse. This significantly reduces the extraction of new, depleting sand resources, as well as the CO2 emissions and cost of handling and transporting them. This unique regeneration technology also significantly reduces the amount of waste sand and the need for landfills.

Finn Recycling has developed the regeneration technology in Nuutajärvi in cooperation with several foundries and universities for almost 10 years. The Sand As A Service (SAAS) model for foundries also enables rapid implementation with low investment. Finn Recycling's mission is to innovate the use and recycling of foundry sand together with its customers and thus be part of the solution to a global environmental challenge.

About Siempelkamp

Siempelkamp is a globally active group of companies with the business units Machinery and Plants, Casting Technology, and Engineering and Service. Nearly 3,000 employees worldwide ensure that the Siempelkamp Group is among the world leaders with its technologies.

The Siempelkamp Foundry in Krefeld specializes in the production of hand-molded large castings of up to 320 tons made of cast iron with nodular graphite. With a casting volume of 50,000 tons per year and more than 400 employees, it is one of the largest hand-molding foundries in the world. The comprehensive and customer-oriented service package includes the entire production process from design, calculations, pattern making, molding and casting to machining, packaging and transport.